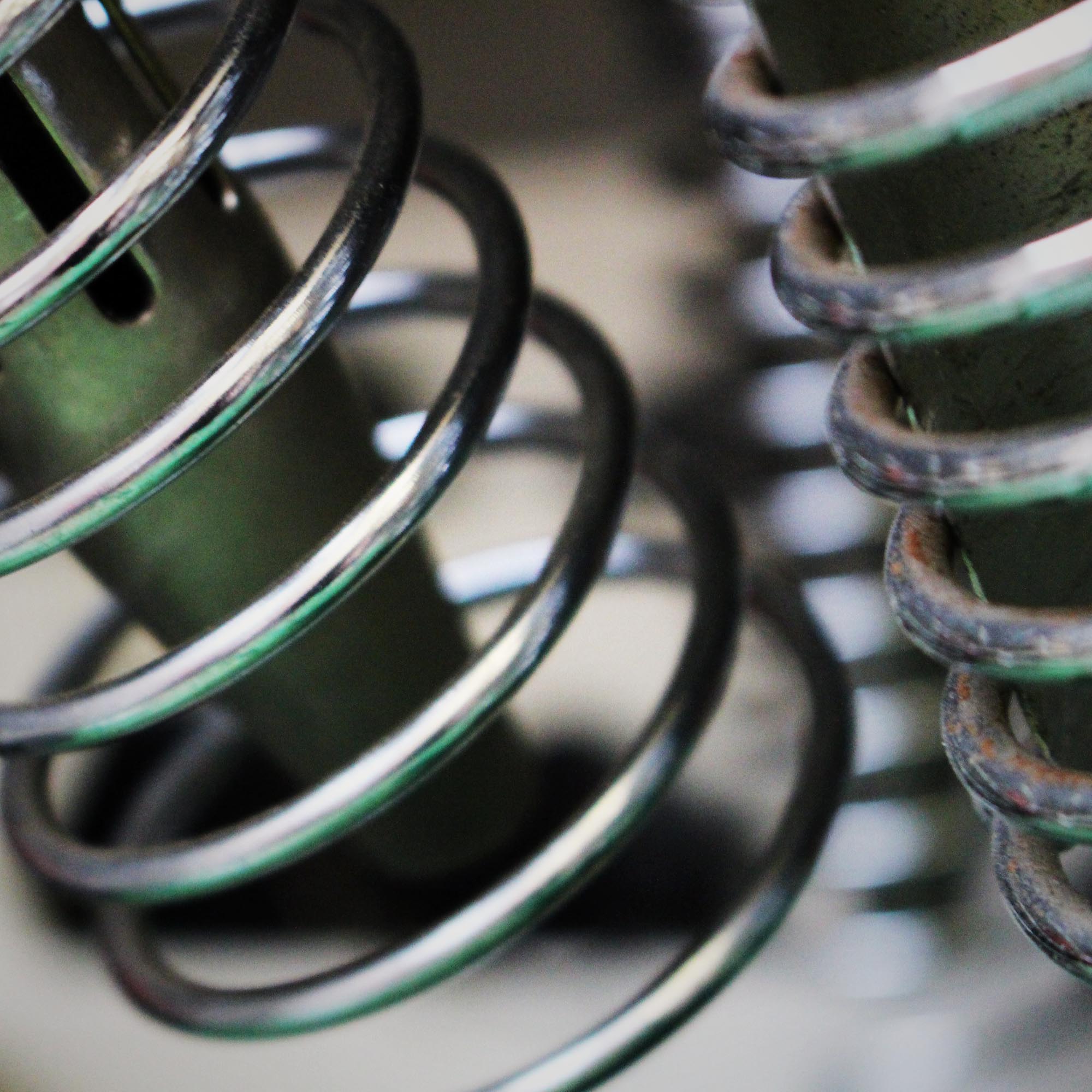

Single Spring & Multi-Spring Mechanical Seals

Understand this key mechanical seal component

Another key element of a mechanical seal is the number springs, which come in two primary types; single spring and multiple springs.

When to use single spring & multi-spring mechanical seals?

A single spring mechanical seal is typically used when the process fluid that is pumped presents little to no risk to the environment and a simple seal will do the job. If the fluid, and its vapour’s, are aggressive at high pressure or temperature, or hazardous to the operator or environment and must be contained, then a more complex, multi-spring mechanical seal is the right choice.

Single Spring Mechanical Seal:

A single spring mechanical seal is a simple structure that does not require any complex method to be applied when using it. It simply acts as the transmission agent between the two systems in between which it is being used. They are designed as a simple design to take care of liquids that are contaminated. They have a naturally high resistance to pressure and heat which is what makes them suitable for use for a long period of time. Because of the simplicity of their design, they are very easy to assemble and dismantle.

Benefits of Single Spring Mechanical Seal

- Simplicity: Easy to install and maintain.

- Cost-Effective: Generally less expensive than complex seals.

- Reliability: Provides consistent sealing performance.

- Versatility: Suitable for a wide range of applications.

- Compact Design: Fits into confined spaces.

- Durability: Handles moderate levels of misalignment and shaft deflection.

- Low Maintenance: Requires minimal upkeep.

- Availability: Widely available and quickly sourced.

Multi-Spring Mechanical Seals:

Alternatively, the multiple spring seals are much more complex in structure and in their usage as well. They were initially designed for the chemical industry but their ability to provide an even loading to all seal faces has made them quite useful in almost all types of industries. Many seal and pump engineers regard multiple spring seals as the best.

Benefits of Multi-Spring Mechanical Seals

- Uniform Load Distribution: Ensures even pressure across the seal faces, reducing wear and enhancing seal life.

- High Reliability: Provides consistent and reliable sealing performance in various operating conditions.

- Compact Design: Suitable for installations with limited space.

- Versatility: Can be used in a wide range of applications, including high-pressure and high-temperature environments.

- Improved Seal Performance: Handles shaft misalignment and axial movement effectively.

- Durability: Designed to withstand harsh conditions, offering long-lasting performance.

- Minimal Leakage: Provides a tight seal, reducing the risk of fluid leakage.

- Maintenance-Friendly: Easier to service and replace due to standardized components.

- Customizable: Available in various materials and configurations to suit specific application requirements.

- Reduced Downtime: Enhances equipment reliability, leading to less frequent maintenance and lower downtime.

The Importance of the Spring in a Mechanical Seal

The spring is a critical component in a mechanical seal, providing the necessary force to maintain contact between the seal faces, accommodating wear and misalignment, and ensuring reliable and effective sealing performance under various operating conditions.

- Maintains Seal Face Contact: The spring ensures continuous contact between the rotating and stationary seal faces, which is critical for effective sealing.

- Compensates for Wear: As the seal faces wear over time, the spring maintains the necessary pressure to keep the seal intact, extending the seal's operational life.

- Accommodates Misalignment: The spring helps the seal adjust to minor misalignments and axial movements of the shaft, preventing leakage and enhancing reliability.

- Absorbs Vibrations: It dampens vibrations and fluctuations in pressure, helping to protect the seal faces from damage and ensuring a stable sealing environment.

- Handles Temperature Changes: The spring compensates for thermal expansion and contraction of the seal components, maintaining consistent sealing performance across a range of temperatures.

- Facilitates Installation and Maintenance: The spring simplifies the installation process by automatically adjusting the seal faces to the correct position, and it helps maintain the correct alignment during maintenance.

- Enhances Seal Performance: By providing a uniform load on the seal faces, the spring ensures even wear and optimal sealing performance, reducing the risk of leaks and extending the seal's lifespan.

- Supports High-Pressure Applications: In high-pressure environments, the spring ensures that the seal faces remain in contact and maintain an effective seal, preventing fluid or gas escape.

Quick guide to single spring and multi-spring seals:

-

Single Spring

- Used for non-clogging and self-cleaning operations

- Assured for long-term usage and higher resistance to heat & pressure

- Very few parts and can be easily assembled or dismantled

- Applications include; viscous, abrasive, crystallising, solidifying & non-corrosive slurry

-

Multi-Spring

- Available unbalanced for low pressure and balanced for high pressure

- Uniform force over the faces increases its life

- Most components are interchangeable so easy to maintain

- Applications include; clear lubricating, non-corrosive & volatile liquids

Order before 2pm to get same day dispatch next day delivery

Have questions on which seal type is best for you?

Our expert team are on hand to help.

Our Mechanical Seals range

Check out our extenisve mechanical seal range, including replacement seals for most major manufacturers: Eagle Burgmann, John Crane, Roten/Uniten, AES, Alfa Laval, Grundfos, MTU, PAC-Seal, US Seal and more.

Our most popular mechanical seals

-

Burgmann MG12 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Roten Type 2 Equivalent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG1 Equivilent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG13 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per

Looking for the perfect seal?

-

Identify the seal you need

Use toolIndentify the seal you need using our Mechanical Seal Idenitifcation tool by selecting the key design features.

-

Know your material

View guideFind out the ideal seal material for your requirement using our Mechanical Seals Materials Guide.

-

Check Chemical Compatibility

Check materialsUse our compatibility checker to ensure you are using the most effective material for your seal.