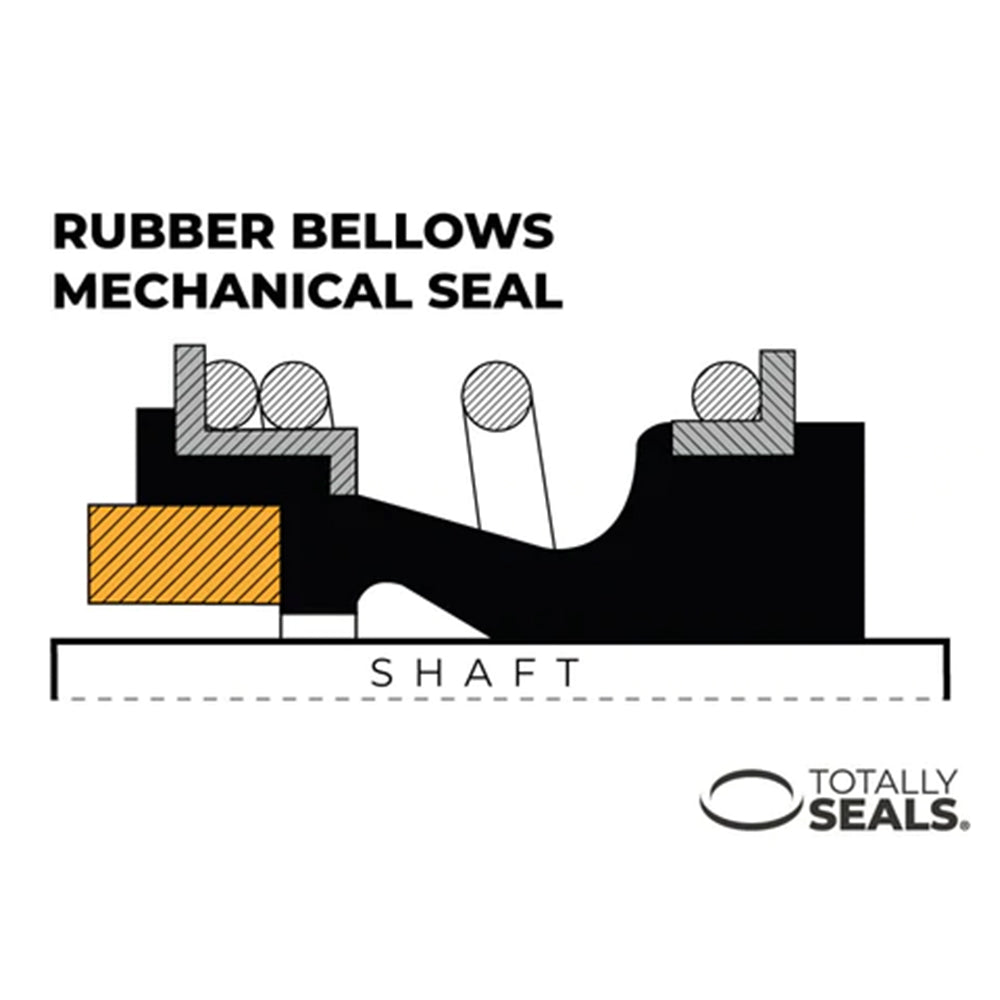

Rubber Bellows Mechanical Seals

High performance, heavy duty, full convolution seals

Rubber bellow mechanical seals are unbalanced, single acting to give optimum strength and robustness. They are built to be the workhorse of seals.

How do rubber bellow seals work?

Rubber (elastomeric) bellows seals function by utilising a compact design and a flexible rubber bellow to provide a reliable sealing action. The high strength and flexibility of the rubber bellow allow it to accommodate seal misalignment, end-float, and seal face wear, making these seals particularly dependable. The bellow is designed to fit tightly around the shaft, with no relative movement between the rubber boot and the shaft or sleeve, thus preventing shaft or sleeve fretting. The sealing action is enhanced by the convoluted bellows profile, which is ideal for media prone to clogging and hygienic applications.

What Are Rubber Bellow Seals Used For?

Rubber bellow seals are mainly used in applications involving water, oils, and light duties. They are commonly found in pumps, compressors, and mixers where these types of fluids are handled. The seals' design makes them suitable for confined spaces and limited gland depths, allowing them to be used in equipment where space is a constraint. Additionally, their ability to handle clogging media and maintain hygiene standards makes them ideal for use in the food and beverage, pharmaceutical, and chemical industries.

What Are the Main Types of Rubber Bellow Seals?

The main types of rubber bellow seals include:

- Standard Rubber Bellow Seals: These are the most common type, designed for general applications involving water, oils, and light duties. They are easy to install and maintain, offering a reliable sealing solution for a wide range of equipment.

- Convoluted Rubber Bellow Seals: These seals feature a convoluted profile that enhances flexibility and makes them suitable for applications prone to clogging or requiring high hygiene standards. The convoluted design helps to prevent the buildup of media on the seal, ensuring consistent performance.

What Are the Benefits of Rubber Bellow Seals?

Rubber bellow seals offer several advantages:

- Ease of Installation and Maintenance: These seals are among the easiest to install, maintain, and replace. They can be easily pushed onto the shoulder, with most designs situated next to the shaft shoulder or linked to the shoulder cast directly into the impeller.

- No Shaft or Sleeve Fretting: Since there is no relative movement between the rubber boot and the shaft or sleeve, the seals prevent shaft or sleeve fretting, reducing wear and extending the equipment's lifespan.

- Accommodates Misalignment and Wear: The high strength and flexibility of the rubber bellow allow it to accommodate seal misalignment, end-float, and seal face wear, ensuring reliable performance over time.

- Ideal for Confined Spaces: The compact design and limited gland depth requirements make these seals suitable for use in confined spaces, expanding their applicability across various equipment types.

- Readily Available: Rubber bellow seals are one of the most common and widely used seals, ensuring that they are always available for quick order and delivery.

Rubber bellow seals are highly effective and versatile sealing solutions for applications involving water, oils, and light duties. Their ease of installation, lack of shaft fretting, and ability to handle misalignment and wear make them ideal for a wide range of industrial applications.

Examples of rubber bellow mechanical seals

The convoluted bellows profile makes these seals slimeline, ideal for media prone to clogging or hygienic applications.

Order before 2pm to get same day dispatch next day delivery

Need help with a rubber bellow mechanical seal?

Our expert team are on hand to help you.

Our Mechanical Seals range

Check out our extenisve mechanical seal range, including replacement seals for most major manufacturers: Eagle Burgmann, John Crane, Roten/Uniten, AES, Alfa Laval, Grundfos, MTU, PAC-Seal, US Seal and more.

Our most popular mechanical seals

-

Burgmann MG12 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Roten Type 2 Equivalent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG1 Equivilent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG13 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per

Looking for the perfect seal?

-

Identify the seal you need

Use toolIndentify the seal you need using our Mechanical Seal Idenitifcation tool by selecting the key design features.

-

Know your material

View guideFind out the ideal seal material for your requirement using our Mechanical Seals Materials Guide.

-

Check Chemical Compatibility

Check materialsUse our compatibility checker to ensure you are using the most effective material for your seal.