PTFE Wedge Mechanical Seals

A robust, high performance, chemical resistant seal

PTFE wedge mechanical seals are built to handle chemical attacks from even the most corrosive fluids, inclduing sulphuric, nitric, phosphoric or hydrochloric acids.

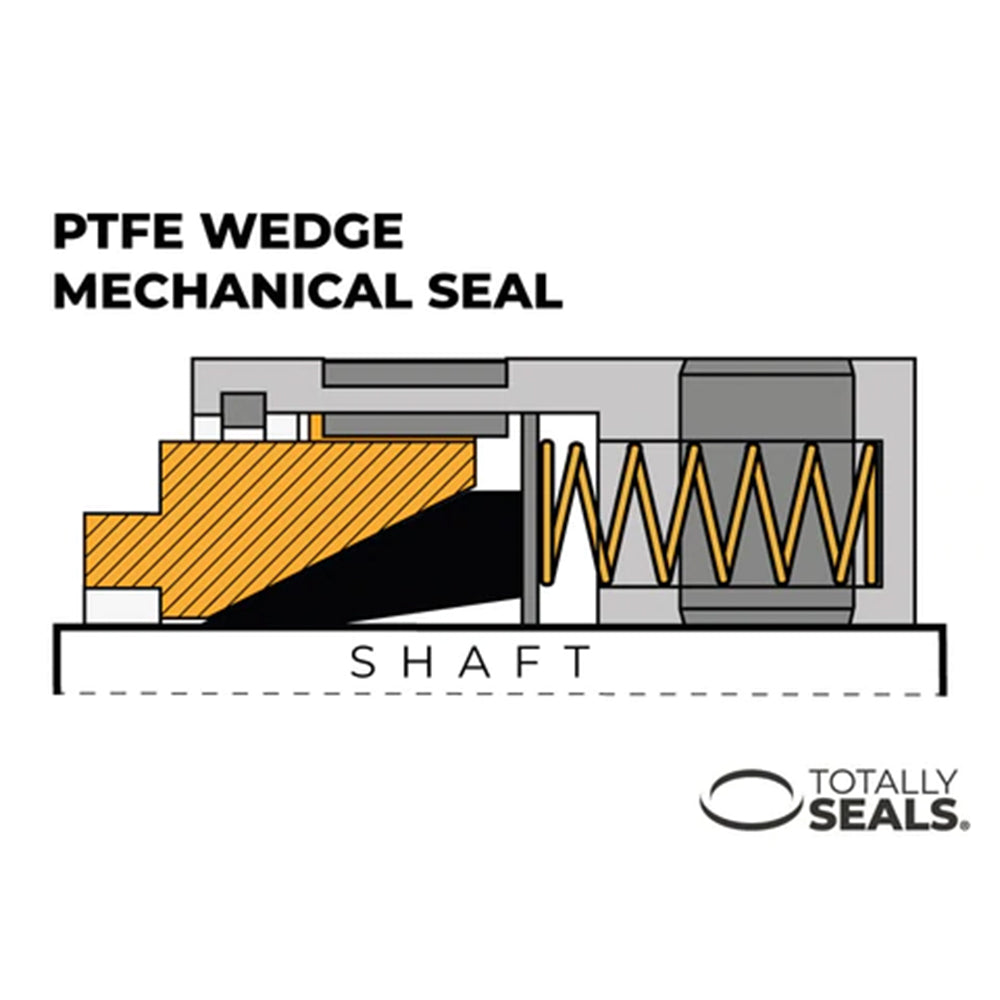

How Do PTFE Wedge Seals Work?

PTFE wedge mechanical seals operate by employing a multi-spring system that ensures the rotating face is pressed against the stationary face, creating an effective seal. The PTFE wedge plays a crucial role in this mechanism. It is designed to locate and stabilize the rotating face while a spring-loaded component forces the flexible angular lip of the wedge into tight contact with the shaft. This force also impacts the rotary face, creating a suitable seal interface. Additionally, these seals can be equipped with an O-ring to form a secondary seal on the shaft, enhancing their sealing capability.

What Are PTFE Wedge Seals Used For?

PTFE wedge seals are primarily used in applications involving extremely corrosive chemicals. PTFE (polytetrafluoroethylene) is renowned for its excellent chemical resistance, making it ideal for sealing solutions in harsh chemical environments. These seals are commonly found in chemical processing plants, pharmaceutical manufacturing, and other industries where equipment is exposed to aggressive substances. The robust design and material properties ensure that these seals maintain integrity and performance under challenging conditions.

What Are the Main Types of PTFE Wedge Seals?

The main types of PTFE wedge seals include:

- Standard PTFE Wedge Seals: These seals use a PTFE wedge to maintain contact between the rotating and stationary faces, providing excellent chemical resistance and reliable sealing performance.

- PTFE Wedge Seals with O-Ring: These seals incorporate an O-ring to form a secondary seal on the shaft, enhancing the overall sealing effectiveness and ensuring additional protection against leaks.

Both types are designed to handle the demands of environments with harsh chemicals, offering versatility and reliability in various industrial applications.

What Are the Benefits of PTFE Wedge Seals?

PTFE wedge seals offer several advantages:

- Chemical Resistance: PTFE is one of the best materials for resisting extremely corrosive chemicals, making these seals ideal for applications involving harsh substances.

- Effective Sealing: The spring-loaded PTFE wedge ensures tight contact with the shaft and sufficient load on the rotary face, creating a reliable seal interface.

- Versatility: These seals can be used with a variety of standard stationary seats, allowing for customization based on specific application requirements.

- Durability: The robust design and material properties of PTFE wedge seals ensure long-lasting performance, even in aggressive chemical environments.

- Enhanced Protection: The option to include an O-ring provides an additional layer of sealing, reducing the risk of leaks and improving overall reliability.

PTFE wedge seals are highly effective and durable solutions for sealing applications involving extremely corrosive chemicals. Their chemical resistance, effective sealing mechanism, and versatility make them ideal for use in demanding industrial environments.

Examples of PTFE Wedge Mechanical Seals

The chemically resistant P.T.F.E. components and wedge seal design make these seals ideal for chemical process pumps and other aggressive media applications.

Order before 2pm to get same day dispatch next day delivery

Looking for a PTFE wedge mechanical seal?

Our expert team are on hand to help you.

Our Mechanical Seals range

Check out our extenisve mechanical seal range, including replacement seals for most major manufacturers: Eagle Burgmann, John Crane, Roten/Uniten, AES, Alfa Laval, Grundfos, MTU, PAC-Seal, US Seal and more.

Our most popular mechanical seals

-

Burgmann MG12 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Roten Type 2 Equivalent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG1 Equivilent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG13 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per

Looking for the perfect seal?

-

Identify the seal you need

Use toolIndentify the seal you need using our Mechanical Seal Idenitifcation tool by selecting the key design features.

-

Know your material

View guideFind out the ideal seal material for your requirement using our Mechanical Seals Materials Guide.

-

Check Chemical Compatibility

Check materialsUse our compatibility checker to ensure you are using the most effective material for your seal.