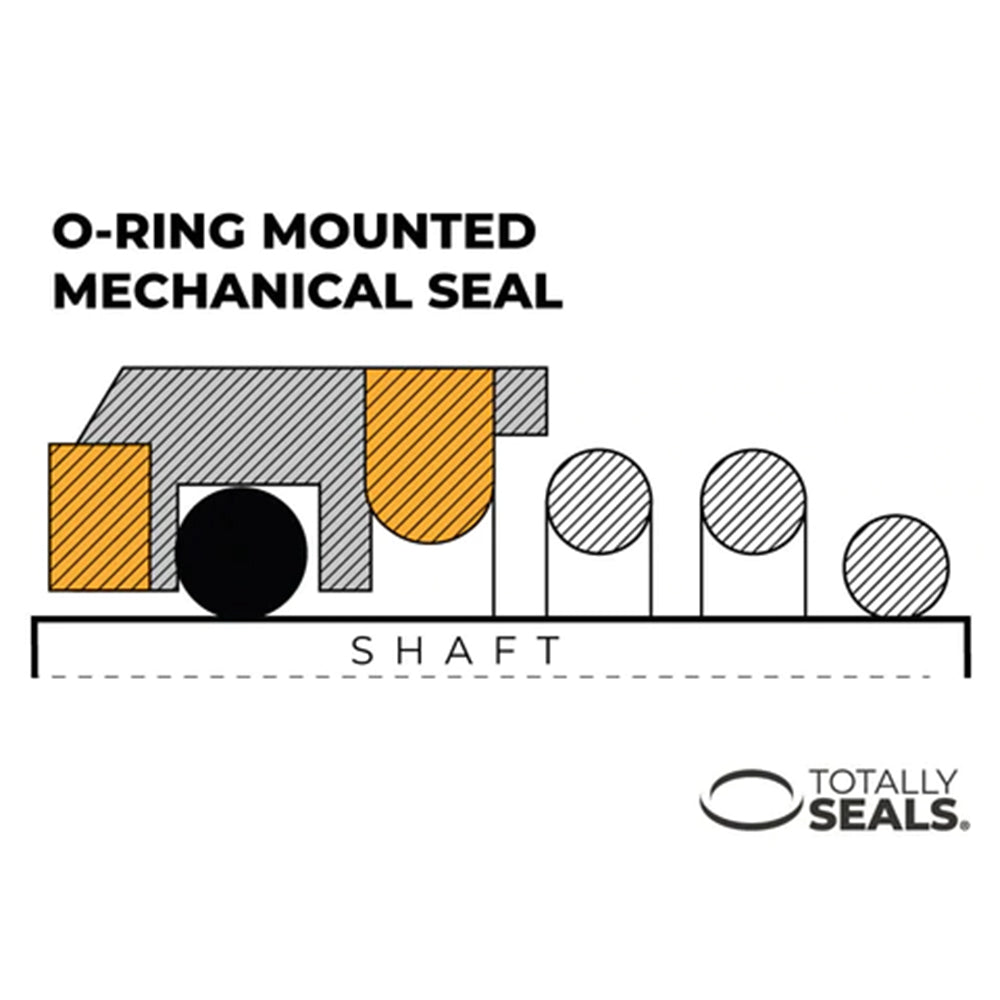

O-Ring Mounted Mechanical Seals

Strong, robust & resilient, ideal for a wide range of environments

The flexibitly of o-ring mounted mechanical seals makes them ideal for standard metric and imperial housing sizes.

How Do O-Ring Mounted Seals Work?

O-ring mounted mechanical seals are essential components in various industrial applications, designed to prevent leakage between rotating and stationary parts. These seals have a small cross-section and a complete recessed O-ring housing. Their narrow seal head width allows them to fit easily into confined DIN 24960 (EN12756) housings. This design not only facilitates installation in tight spaces but also offers benefits such as reduced face surface running speed and increased circulation around the seal faces.

Seal loading is typically achieved using conical springs or wave springs, with conical springs being the most prevalent. These springs ensure that the seal is tightly gripped and maintains optimal contact pressure against the rotating shaft. Conical spring seals usually come with right-hand drive springs for clockwise shafts, but left-hand springs are available for anticlockwise rotation upon request. Wave springs, on the other hand, allow for extremely compact seal designs in both axial and radial directions. They provide equal loading and deflection at a fraction of the free height compared to helical springs, making them ideal for use in limited spaces.

What Are O-Ring Mounted Seals Used For?

O-ring mounted seals are used in a variety of applications across multiple industries. Their primary function is to prevent fluid leakage in systems where there are rotating shafts, such as pumps, compressors, and mixers. These seals are particularly useful in environments where contaminants are a concern, such as in the food and chemical industries. Their design makes them suitable for restricted fitting applications prone to clogging, ensuring reliable performance even under challenging conditions.

What Are the Main Types of O-Ring Mounted Seals?

The main types of O-ring mounted seals include:

- Conical Spring Seals: These seals use a conical spring to grip the shaft, providing reliable seal loading. They are typically used for applications with clockwise shaft rotation but can be specified for anticlockwise rotation if needed.

- Wave Spring Seals: These seals utilise wave spring technology to create extremely compact seals. Wave springs offer equal loading and deflection at a reduced height compared to helical springs, making them ideal for limited space applications.

Both types of seals can be customised with various face materials and spring/seat sizes to suit specific application requirements.

What Are the Benefits of O-Ring Mounted Seals?

O-ring mounted seals offer several advantages:

- Compact Design: The narrow seal head and full recessed O-ring groove allow these seals to fit into tight spaces, making them versatile for various applications.

- Reduced Running Speed: The design reduces face surface running speed, which helps in prolonging the seal life and enhancing performance.

- Improved Circulation: Increased circulation around the seal faces helps in maintaining optimal operating conditions and prevents overheating.

- Versatility: These seals can accommodate misalignment and vibration, making them suitable for a wide range of applications.

- Insensitivity to Contaminants: Their design makes them less susceptible to clogging, ensuring reliable performance in environments with potential contaminants.

- Easy Installation: The straightforward fitting process simplifies maintenance and reduces downtime.

O-ring mounted seals are highly efficient and versatile solutions for preventing leakage in various industrial applications. Their compact design, reduced running speed, and ability to handle contaminants make them ideal for use in the food, chemical, and other industries where reliable sealing is critical.

Examples of o-ring mounted mechanical seals

A narrow seal head width allows easy installation, whilst also providing the benefits of reduced face surface running speed, with increased circulation around the seal faces.

Order before 2pm to get same day dispatch next day delivery

Looking for an o-ring mounted mechanical seal?

Our expert team are on hand to help you.

Our Mechanical Seals range

Check out our extenisve mechanical seal range, including replacement seals for most major manufacturers: Eagle Burgmann, John Crane, Roten/Uniten, AES, Alfa Laval, Grundfos, MTU, PAC-Seal, US Seal and more.

Our most popular mechanical seals

-

Burgmann MG12 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Roten Type 2 Equivalent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG1 Equivilent Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per -

Burgmann MG13 Equivilant Mechanical Seal

Regular price From £117.19 GBPRegular priceUnit price / per

Looking for the perfect seal?

-

Identify the seal you need

Use toolIndentify the seal you need using our Mechanical Seal Idenitifcation tool by selecting the key design features.

-

Know your material

View guideFind out the ideal seal material for your requirement using our Mechanical Seals Materials Guide.

-

Check Chemical Compatibility

Check materialsUse our compatibility checker to ensure you are using the most effective material for your seal.